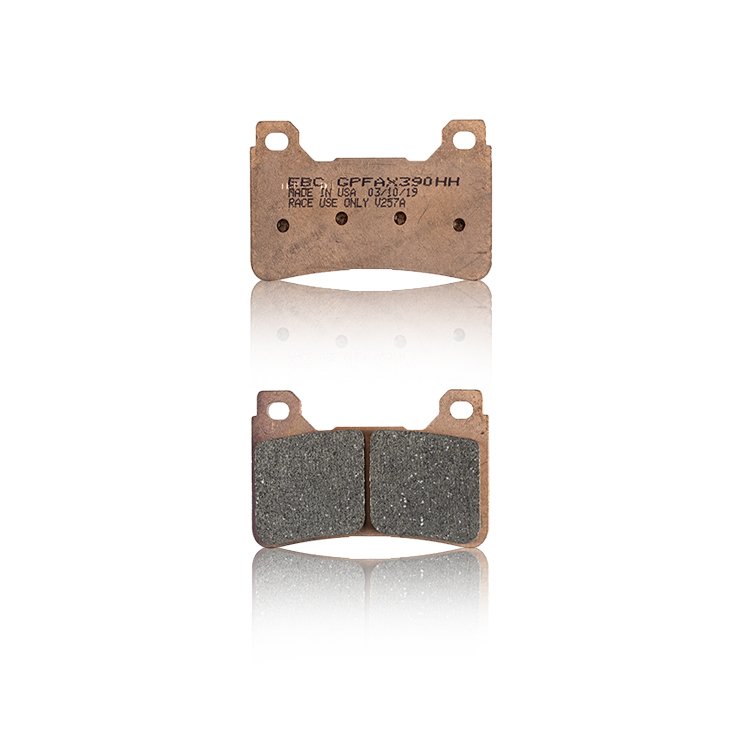

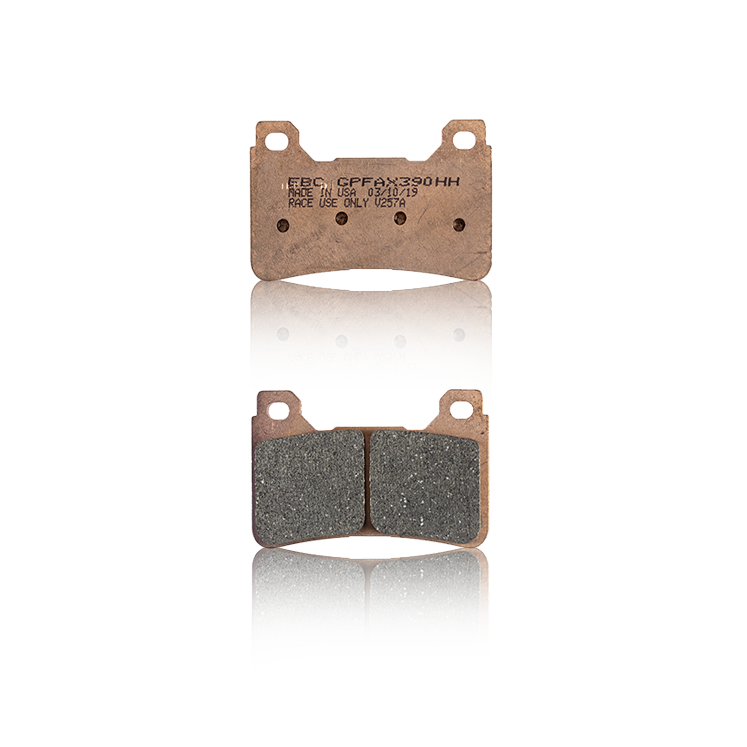

GPFAX Sintered Race Brake Pads are for RACE ONLY use. This is a blend of brake pad that has higher friction and far better grip than any other brake product on the market.

EBC GPFAX Sintered

Racing Brake Pads

Race Brake Pads

GPFAX Sintered Race Brake Pads have by far the highest known friction with a measurement between 0.6 and 0.7 and deliver the most amazing brake effect. Because of this factor, they are unsuitable for street use or for road tyres.

Zero brake fade is guaranteed and the heat stability of these brake pads is perfect leaving the racer with high confidence and a product that can be used over numerous races.

GPFAX Sintered Race brake pads are a closed circuit use pad only and street/highway riding with this material is highly inadvisable and dangerous. Such high friction levels as delivered by these pads are for ideal track conditions with race tyres or slicks on prepared asphalt surfaces and NOT for use with highway tires or on the highway. This material is not ECE R 90 approved nor TUV tested with a German ABE and use on the highway is therefore illegal in many countries.

Features and Benefits

- Made in the EBC plant in Ohio, USA

- Ultra-high friction face resistant compound

- Superb heat cycling ability, pads perform consistently race after race

- Built on hard steel SN series backplate steels to resist warping and brinelling of surfaces under heavy loads

- Not R90 street legal or TÜV tested (a requirement for European Markets only)

Statement of Race Use

Racing is a dangerous sport and EBC wishes to advise all users that any and all liability using any EBC products for any kind of Motorsport, track day event or racing lies purely and exclusively with the user. There is no liability or guarantee nor responsibility accepted by EBC brakes or its affiliates or officers for incidents or costs occurring in such race use.

Technical Information

Preparing your race discs/rotors before using this Compound

Many pads contain carbon particles some in high percentages and this leaves a grey glaze on rotors. This MUST be removed by fine abrasive paper or what is known as a Scratch Pad in the USA. Take care not to promote deep scratches on the rotor which will cause prolonged bed in times.

Bedding in your new brake pads

After installing the pads ride the bike for 2 laps very gently applying the brakes well in advance of where you wish to stop at speeds not exceeding 80 MPH. Proceed a further 2-3 laps gradually increasing the brake load until you feel the pads become stable and predictable.

Bedding in to worn or distorted discs/rotors will be dramatically longer.

Inspect pads every Race for wear on EACH pad and replace when any single pad is down to 2.5 mm or lever becomes spongy. Different brake systems respond differently and have differing amounts of fluid in their piston chambers and the time for ideal replacement of the pads due to loss of brake feel can only be assessed by the individual rider and bike.

Brake fluid considerations

Old brake fluid affects sponge and brake feel. Most brake fluids are Glycol based and over time their hygroscopic nature means they will absorb moisture even through the brake lines. As amazing as this sounds it does happen and fluids can contain as much as 12% water by volume in worst cases.

It is highly advised to replace brake fluid every 6-8 race events as a minimum with a high wet boiling point fluid such as EBC Race fluid. Use only fluids from a sealed container, never from a bulk can or drum as in this storage condition the fluid will act as an old material even before you use it having absorbed water since originally opened.

Brake discs/Rotors for race use

EBC recommends either its X or XC brake rotor options for race use. These are fully floating discs/rotors made 100% in the UK from precision billet alloy centres connected using stainless SD system square-sided drive buttons to German mill rolled, heat treated, and tempered brake rotor blades. This makes the EBC rotor a tough and long-lasting, crack-resistant design, fully floating to ensure they handle the heat of racing.

This link takes you to more information about these brake rotors.