BSB Racer Max Symonds Tests EBC Components at Spain’s Jerez Circuit

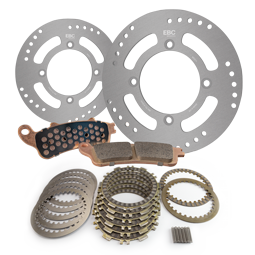

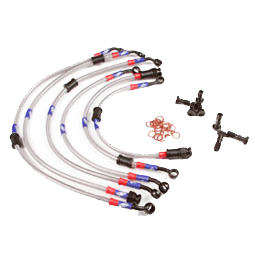

The BSB Superstock rider will use EBC parts on his Yamaha R1 for the 2024 season British motorcycle racer, Max Symonds, competes in British Superbike’s National Superstock category on his…

Superbike Racer Andrew Smyth Shows Promise at Kirkistown Race

The EBC-equipped racer is warming up for another BSB season Northern Ireland-based Andrew Smyth of the Andrew Smyth Racing outfit has successfully competed in BSB’s Superstock 600 series for the…