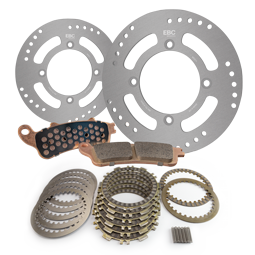

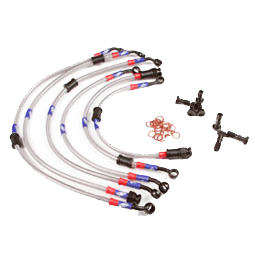

Top-quality brake products from the World Leading Brake Specialists

Filter

Can't find what you're looking for?

The EBC Brakes team is always happy to help. If you can't find what you're looking for, please don't hesitate to get in touch via our Contact page. But be sure to check our FAQ's first, in case your query has already been answered.