What Are the Best Car Brake Pads to Buy?

That’s a tough question, but we’ll give it our best shot.

First of all, it’s not so much about what is the best as it is about what is RIGHT for your vehicle and your driving style.

If you don’t want to read this long article, jump straight to the conclusion.

A Few Useful Pointers:

Consider the Manufacturer’s Track Record

- EBC is a British and American brake manufacturer producing the largest range of brake pads anywhere. After producing over 50 million sets of brake pads in recent decades, EBC Brakes has extensive experience and offers six different material blends for motorcycles and eight for automotive applications.

At EBC Brakes, we understand the importance of choice.

- Does the Brand Actually Manufacture the Brakes They Sell?

Many “big brand” names selling brakes don’t actually make brake pads; they outsource production to factories and package them under their brand name, hoping the household name provides “comfort.”Comfort doesn’t stop vehicles—quality does!

- Is There an ECO Standard to Ensure Pads Are Environmentally Friendly?

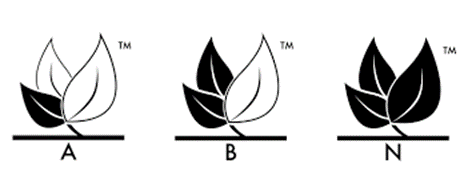

Yes, there is a U.S. system called the “LEAF MARK SYSTEM”, for automotive brake pads developed by the Department of Ecology in the State of Washington. It rates pads based on their eco-friendly nature using a leaf or petal system. The darker the petals or leaves , the more eco-friendly the pad.

(Please note copper content or leaf mark rules do not apply to motorcycle brakes as they carry an exemption)

Look for the Leaf:

The Brake Manufacturers Council adopted the LeafMark to inform customers whether a brake pad meets the Better Brakes standards. The darker the leaf, the more levels of compliance the pad meets:

- Level A: Limits levels of asbestos, cadmium, chromium, lead, and mercury.

- Level B: Includes all the requirements of Level A, with copper levels less than 5% by weight.

- Level N: Includes all the requirements of Level A, with copper levels less than 0.5% by weight.

All production of EBC pads are now at petal standard N the very best

Are the Brakes Made to Any Known Standard?

- In Europe, there is the EU regulation R90, a rigorous test that results in a simple yes or no answer: Do the brakes meet or exceed the original brakes on your vehicle? Approved brakes are labeled on the packaging and on the pads themselves, typically with a country-specific E number followed by a 12-digit manufacturer code. Read more about R90 here.

- In the USA, there is the FMVSS (Federal Motor Vehicle Safety Standards), which only codes friction levels and does not evaluate longevity or brake torque, which EBC tests for regularly.

Are They Made Using the Latest Available Technology?

- In the brakes industry, there have been three major technological advancements: the abolition of asbestos (which EBC has never used), the rise of NAO (Non-Asbestos Organic) materials, and the introduction of Ceramic granule compound enhancement. EBC has only ever made NAO materials for automotive and organic non-sintered motorcycle pads.

Important Considerations for Pad Safety

- A few years ago, EBC established a completely new plant in their Northampton pressworks to apply NRS “velcro-like” hooks to all automotive backing steels.Read about this here.The use of NRS technology sets EBC apart from most other pad manufacturers, ensuring there is no “debonding” of the pad from the backing plates.

The image below shows a typical non NRS backplate surface after debond

Motorcycle Brakes

- For motorcycles, EBC has its own plant in Ohio producing tens of millions of high-quality sintered metal brake pads.

- EBC also manufactures semi-sintered motorcycle pads (Vee pads) at its Bristol, UK plant.

- EBC has been the primary choice for motorcyclists worldwide, with over 30 million riders using EBC products. It’s a strong track record. Buying a low-cost, unknown pad online might seem fine, but they may only work for a few thousand miles. You may see glowing reports (often suspected to be by the sellers themselves), but safety on a two-wheel vehicle is even more critical. Remember the old Bell Helmets ad: “If you have a $10 head, buy a $10 helmet.” That pretty much says it all.

What’s Important for You as the Driver or Rider?

- Stopping better at speed or under heavy loads

- Stopping without noise

- Long-lasting durability

- Being eco-friendly

- Low price

EBC Brakes can provide solutions for all these factors in our brake selector chart. But remember, low price does not always mean reduced cost. Many cheaper pads cost more in the long run as they wear quickly or can even self-destruct by debonding from the backing plate, especially in wet and humid conditions.

Debonding mainly occurs on rear axle pads of cars and trucks, where water splash causes constant moisture at the pad-to-backplate interface. However, it can also happen on the front or rear of motorcycles, which are constantly exposed to the elements.

Conclusion

The right brake pads for your needs are more important than any bold claim about “the best brake pad.” There is no single best choice; you need options, as shown in our brake selector chart. That’s what EBC offers like no other brake company.

Safe driving/riding, folks!