We answer some of the most frequently asked questions from the world of performance braking

You probably don’t need us to tell you that there are often a large number of myths and debates revolving around the world of vehicle braking. In this article, we aim to answer some of these queries once and for all…

- Q) How often should brake fluid be changed?

A) Every two years for normal road use, or every 2-3 visits to the race track for a vehicle used frequently on the circuit. - Q) How do I choose the right type of brake fluid?A) Most vehicles use Glycol DOT 3 or DOT 4 fluid – see the top of your master cylinder or owner’s manual for more info.

- Q) What’s the difference between DOT 3/4/5 brake fluids?

A) DOT 3 and 4 are effectively the same, with DOT 4 being purer. DOT 5 can be silicone or glycol variants and cannot be interchanged with DOT 3/4. - Q) What type of brake fluid is used for racing?A) A DOT 4 high-temperature version is best, such as EBC’s BF 307 fluid.

- Q) What is ‘dry boiling point’ and ‘wet boiling point’?A) The dry boiling point refers to when fluid is new from an unopened bottle. The wet boiling point is when the fluid is used and needs changing (where the water content is past 3%).

- Q) Why is dry boiling point higher than wet boiling point?A) This is because the moisture content of a brake fluid boils at a lower temperature, therefore the wet boiling point will be lower.

- Q) What are brake caliper seals made of?A) Most vehicles use EPDM rubber, while a few use Nitrile rubber. A third, rarer version is Viton.

- Q) How often should brake caliper seals be changed?A) Every 2-3 years in road use, or every few races on the track, or if the caliper body reaches temperatures over 250°C.

- Q) What is the maximum safe temperature for caliper seals to be exposed to?A) EPDM seals (the most popular type) are not designed for use above 140-150°C, which corresponds to a caliper body temperature of about 250°C.

- Q) How hot do my discs/rotors get and what does this mean for my pad compound selection?A) Heat paints are a handy tool in telling you exactly what products you should be using.

EBC Brakes offers three heat paints which can be brushed onto the outer edge of the rotor before racing, to detect temperatures. The EBC Brakes rotor paint kit also includes 10 caliper heat strips.

The rotor paints supplied are:

#1 – 800°F/430°C

#2 – 1000°F/540°C

#3 – 1200°F/650°C

Paint all three separately in lines on your disc/rotor edge.

The temperature at the centre of the brake pad will always be on average 100°C/200°F more than the outer edge of the rotor in race use. If your rotor edge is not setting off the 430°C paint line, all EBC compounds will be fine.

If the 430°C paint line activates (530°C at the centre of the pad), you’re at the limits of EBC’s Bluestuff pad.

If the disc/rotor outer edge temperatures exceed 540°C (640°C approx. at the pad centre), you are past the limits of EBC’s Bluestuff and need to switch to EBC Brakes Racing’s RP pad range.

If the 650°C paint line goes off (750°C at the pad centre), you’re definitely in need of either the RP range or SR series of pads.

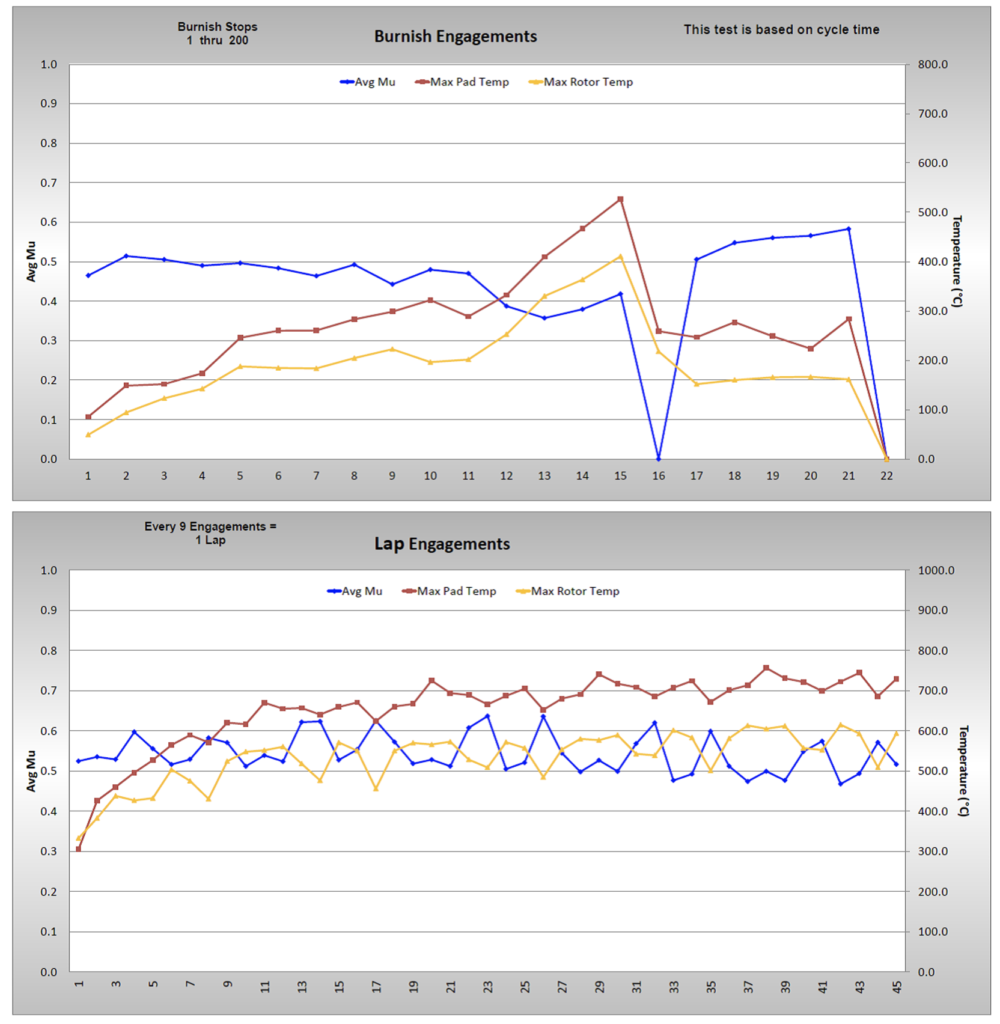

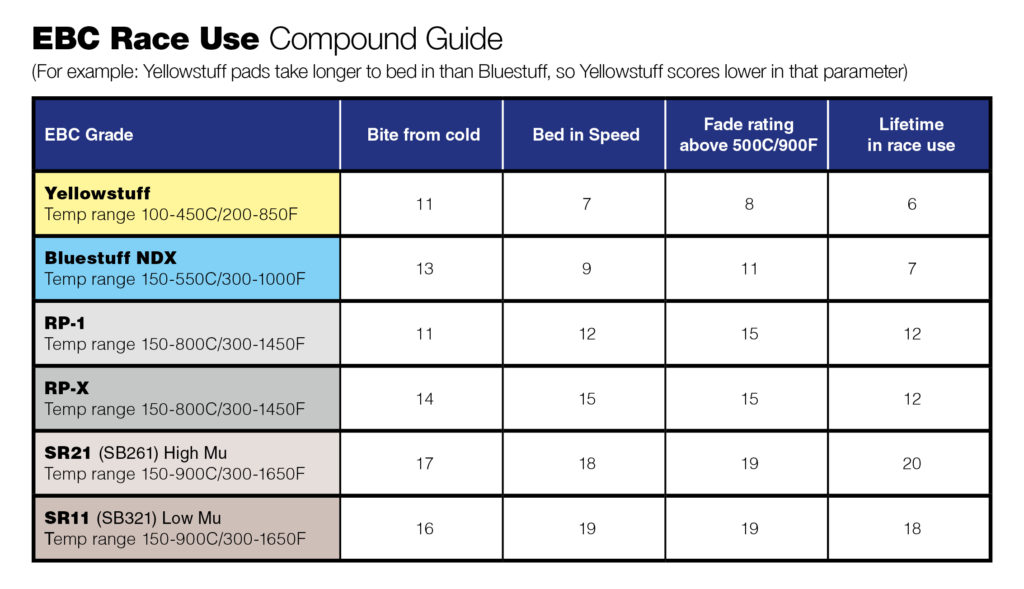

Here is a guide on EBC Brakes compounds and their temperature ranges:

(The curves below show that on average in race use, the pad temperature runs at approx. 100°C above the disc/rotor outer edge:)