Welcome to

EBC Brakes Rail

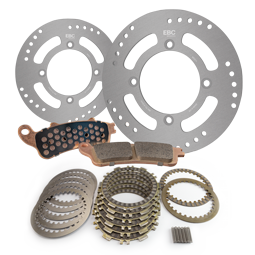

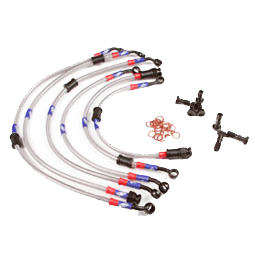

With a worldwide work force of over 400 people, EBC Brakes is an independently owned and managed leader in the brake market, proud of its customers, its products, its success and its people. EBC Brakes produce the largest range of brake pads and brake discs in the world, with over 5000 part numbers for every type of moving vehicle. EBC Brakes are made in one of its two specialist factories in the UK and USA.

From our global headquarters in Northampton, EBC Brakes offer total support for its products, from development and performance testing, to packaging and delivery scheduling, and with service monitoring and advice.

For over 25 years EBC Brakes have been supporting their rail customers directly from their factory, European Friction Industries Ltd. Known throughout the industry as EFI, they have been involved in material development for OE projects across the USA as well as OE and aftermarket products for some of the largest light rail applications in the UK.

About EBC Rail

From humble beginnings back in 1983 in Northampton, UK, EBC Brakes was established and was initially based out of one of Northampton’s many now defunct shoe manufacturing buildings.

The company was founded due to one man’s passion for motorcycles at a time in the 80’s when he realised that there was a demand for more choice other than original equipment and the need for better quality, more advanced brakes in the UK market.

Whilst some friction manufacturers focus on producing only one type of product EBC has, for the last 37 years, been producing such a diverse range of brake pads that it is widely considered to be the world’s largest range. All of its products are produced from the company’s two ISO9001 accredited friction sites in the UK and USA, both of which are wholly owned by EBC Brakes.

Today the company’s heritage remains as the Head Office and World Wide Distribution Centre are still located in Northampton; however, it is now based in a purpose-built, modern, 300,000 square foot site, together with a massive 14 acres of additional land for future expansion, which already has planning permission for two new buildings … it’s from here that their full range of products are distributed globally.

EBC Brakes have produced and sold millions of brake pads for all types of vehicles and with modern trends towards cheap imported brake products, EBC leads the world in its technology, quality control, product performance and customer service. Their product range includes brakes for nearly every moving vehicle on the planet from military, industrial and wind turbine brakes through to railway rolling stock.

In the demanding and competitive world of friction materials where quality, performance and safety are paramount, EBC Brakes offer total support for its products, from development and performance testing to packaging and delivery scheduling and with service monitoring and advice.

Research and development are the driving force of any successful brake manufacturer and EBC Brakes is proud of its extensive facilities with dedicated laboratories, which include full chemistry friction development testing on their dynamometers, including a full scale rail dynamometer.

EBC Brakes are always at the forefront of technological advancements within the friction industry and no matter what the purpose of the brake pad; no products are produced using any harmful ingredients such as asbestos, lead or heavy metals such as mercury or antimony oxide. In fact EBC is now setting the bar higher by removing copper, a key ingredient in most brake pad compositions, from its range of organic brake pads to make its brake pads more environmentally friendly.

Over 25 Years

For over 25 years EBC Brakes have been supplying rolling stock customers worldwide directly from their factory in Bristol UK, known and respected across the globe as European Friction Industries Ltd or EFI.

EFI has a very long and impressive history in the friction materials world having started out back in the 1980’s as a collaboration of skilled ex-employees from other well know friction manufacturers that were also based in Bristol, back in the days when Bristol was more or less the UK’s epicentre for friction materials manufacturing.

EFI have been involved in material development for OE projects for EBC Brakes across the USA as well as aftermarket products for some of the largest light rail applications in the UK and in many cases their products have been so reliable that even though the rail franchises may have changed hands several times, EFI’s products have been used continuously for several decades; quite an impressive feat to say the least in today’s competitive world!

Tram Systems

EBC Brakes currently offer five market-proven materials for light rail and tram systems, each of these having been developed for different types of vehicles. As part of their market development, new materials are currently being produced specifically for UK mainline rail vehicles. EBC understand that one material will not always suit applications of the same reference; individual operating requirements, rolling stock variations and local regulations will all have an effect on the materials being produced. EBC Brakes are able to run dynamometer tests before recommending any material and if necessary can modify materials for each application. At their factory, a full-size rail dyno is used to test disc brake pads to national and international specifications, as well as to individual route simulations.

Quality is one of the most important aspects of any product used within the railway industry and EBC has been certified to ISO9001 for many years, however in order to enhance their position as a leading quality friction supplier to a global market, EBC’s factory, EFI, is now working towards becoming IRIS certified. EFI is also a RISQS verified supplier to the UK rail industry.

The Most Common Pads for

Air Brakes

- EBC Brakes have the capability of manufacturing a large number of railway disc brake pad designs, including all of the common UIC type pads.

- The UIC pads are the most common pads for air brakes on railway rolling stock; however we also manufacture a comprehensive range of other types of disc pads for railway applications.

- We have the ability of manufacturing all of our pad types in any of our materials. For our railway disc pad range, we would not recommend a material for an application, until we have a full understanding of the requirements of the particular service the pad is intended for.

Market Proven

- EBC Brakes currently offer five market-proven materials for light rail and tram systems, each of these having been developed for different types of vehicles. As part of our continued market development, new materials are currently being produced specifically for UK mainline rail vehicles.

- We understand that one material will not always suit applications of the same reference; individual operating requirements, rolling stock variations and local regulations will all have an effect on the materials being produced.

- Through our factory, we are able to run dynamometer tests before recommending any material and if necessary can modify materials for each application. The European Friction Industries full size rail dynamometer is able to test disc brake pads to international and national specifications, as well as to individual route simulations.