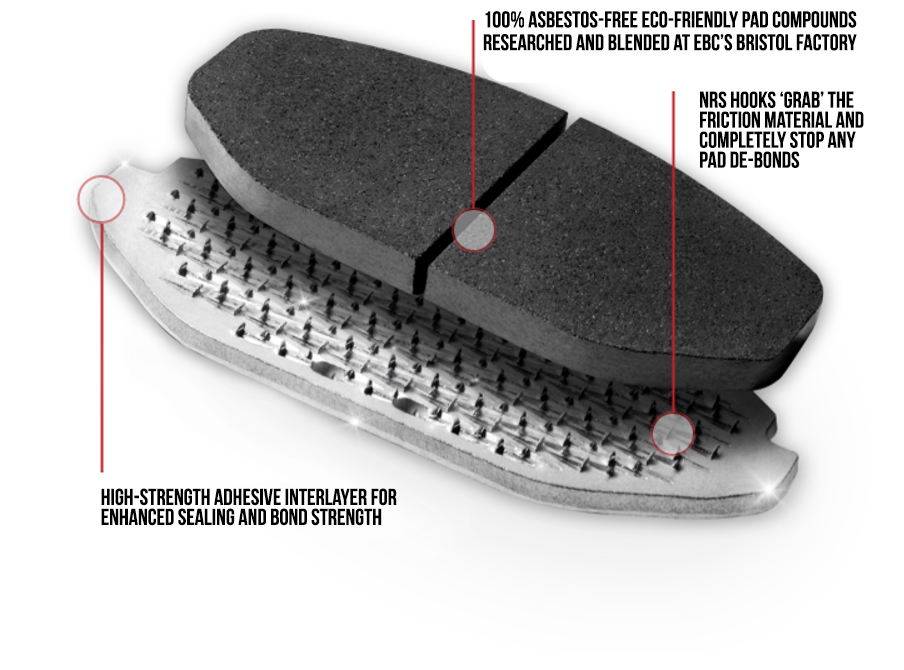

EBC Brakes Pad Backplates are secured with NRS Hooks

100% asbestos-free, eco-friendly pad compounds researched and blended at EBC Bristol

High strength adhesive interlayer for enhanced sealing and bond strength.

NRS hooks “Grab “ the friction material and completely stops any pad debonds.

NRS is the trademark of Nucap Industries in Canada and is used under a license from them. NRS stands for Nucap retention system which is a process to form up-turned bi-directional crescent-shaped projections standing on average 1.0 mm above the backing plate formed by an elaborate pressing process. EBC have built their own presses and tools in conjunction with and under the supervision of Nucap to ensure a perfect process at its Northampton pressworks facility.

The projections or hooks are thereby integrally built into the pad to plate contact area during molding and form a massively secure bonding of the friction material to the backing plate.

Tests have shown that the shear strength of the pad to friction bond is increased by up to 6 times using NRS.

EBC also spray coats heat-activated glue onto the backing plates in all non-stainless backing plates used in the manufacture of EBC pads to seal the surface, increase bond strength even further and prevent interlayer corrosion.

Friction material debond is a thing of the past with NRS and EBC.

It is also not always good to wait for the pads to be completely worn out for another reason. Pad compounds can die which brings us to the second point.

EBC even go one step further. Although common practice suggests that pad adhesive (dry heat cured glue) is not required when using NRS …..EBC still applies copious spray adhesive over and amongst the NRS hooks. The logic for this is that if interlayer corrosion sets in around the edges of the pad beyond where the NRS hooks extend it can LOOK bad by showing a hairline gap around the pad material. Adding adhesive seals the edges and prevents water ingress providing a belt and braces bonding security. So hooks plus glue plus alkaline compound additives and we have the EBC triple secure system.

We know of no other pad manufacturer taking these steps to deliver a perfect product to its customer base.

Ask your chosen pad supplier if THEY use NRS before buying