A round-up of the latest products and news stories from EBC Brakes this month LATEST EBC PRODUCTS Suzuki Swift Sport (Z32) – Balanced Big Brake Kit Four-piston Apollo Balanced Big…

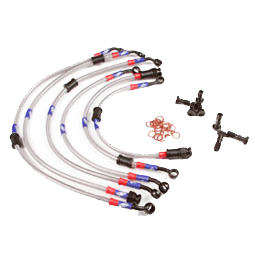

EBC Brakes now manufactures these high-quality clip-on brake pad wear leads in-house EBC Brakes is proud to announce the in-house manufacturing of high-quality brake pad wear leads, designed specifically for…

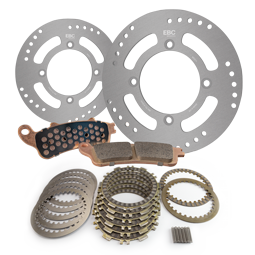

Need an upgrade in braking performance? EBC Brakes' wide range has the answer If your vehicle's braking performance isn’t meeting your expectations—whether you drive a car, truck, or motorcycle—EBC Brakes…