EBC Brakes Racing Apollo Big Brake Kit Now Available for Hyundai i20N

EBC Brakes Racing’s Apollo Big Brake Kits offer one giant leap forwards for the performance braking market EBC Brakes Racing’s Apollo Big Brake Kits represent the ultimate upgrade when it…

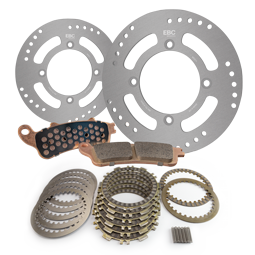

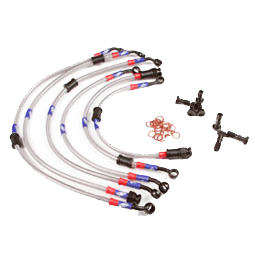

BSB Racer Max Symonds Tests EBC Components at Spain’s Jerez Circuit

The BSB Superstock rider will use EBC parts on his Yamaha R1 for the 2024 season British motorcycle racer, Max Symonds, competes in British Superbike’s National Superstock category on his…