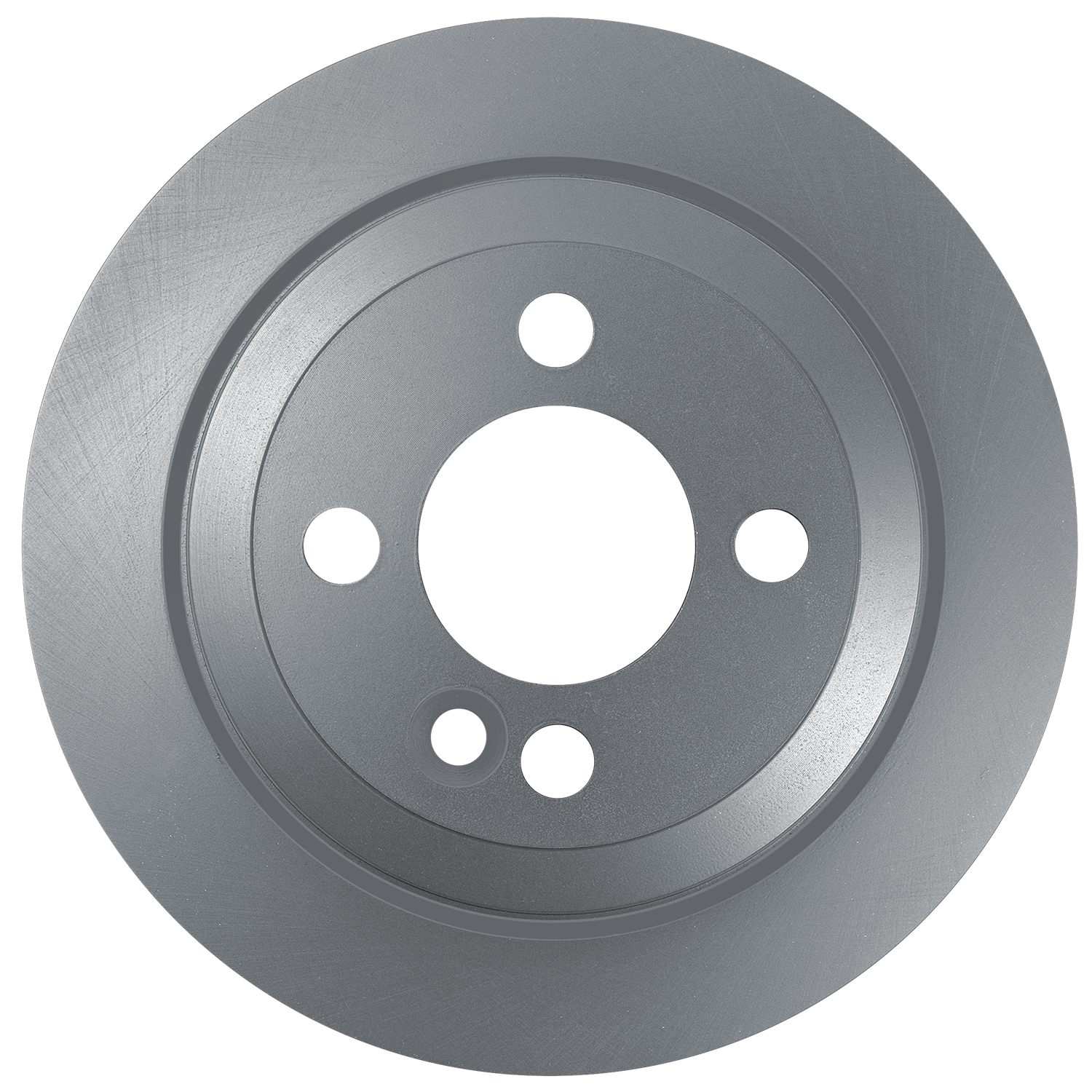

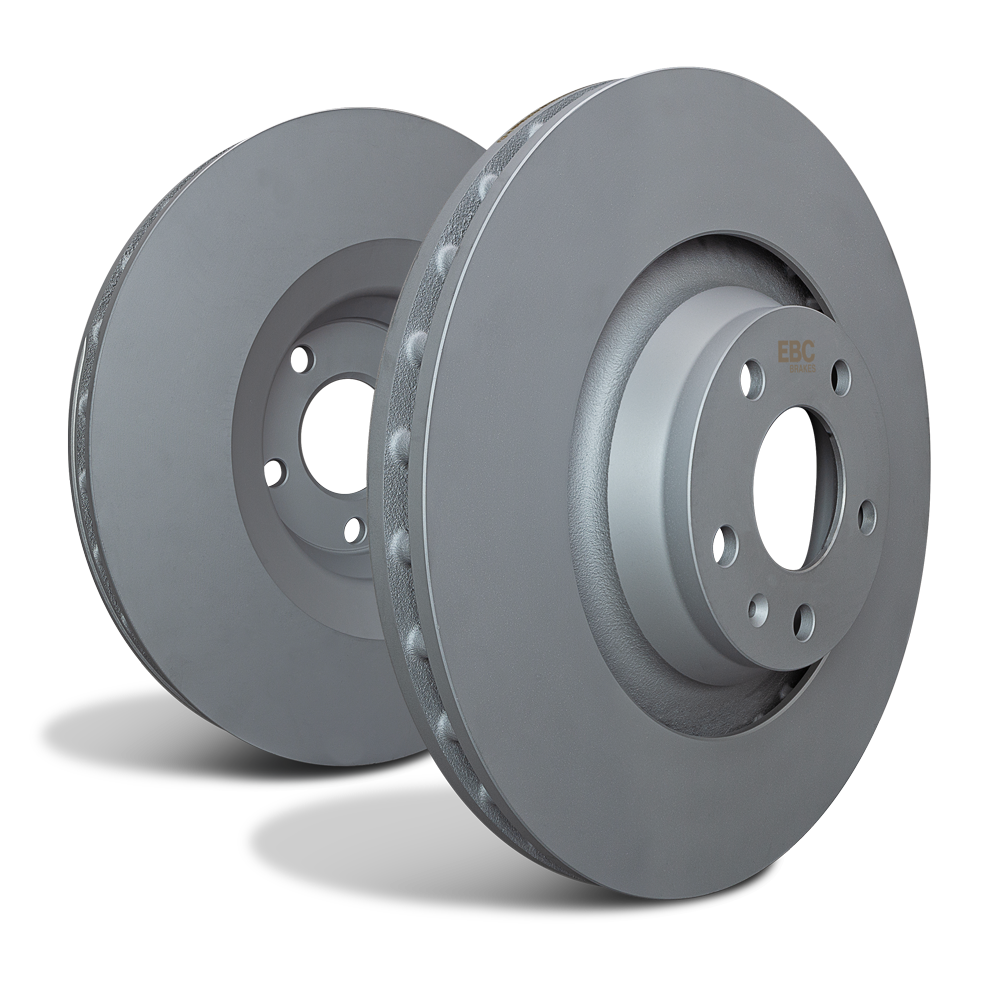

EBC Brakes are quickly switching to its latest Gen 3 silver grey disc rotors. All disc rotor materials and drill or slot patterns will remain the same except the base rotor will be Silver Grey. This new surface coating is a highly corrosion-resistant rust prevention coating and is now on all current production of EBC Brake rotors.

New GEN 3 Silver Grey Rotors and the Logic Behind It

In the past few years, EBC Brakes has enhanced its rotor production facilities, now over 80% of our rotor castings are produced in Europe and 100% of machining for sport rotors is done in either the UK or the USA.

EBC switched in early 2023 to a new silver grey Geomet style coating color, the photograph opposite from the AutoSport show a few years ago, shows what our rotors looked like before and the photo below shows the new product

The Reason For The Switch

- Silver color leaves the rotor hat or hub silver in appearance after bedding in – more likely to match a vehicle’s original rotor colors, so the front and back of the car look similar if you have only changed one axle

- The new silver finish has far higher corrosion resistance to the former black etch paint (thermic black versions)

- Painting is now done as a part of the rotor production process in the actual casting plant. This facility is more environmentally friendly, and air quality controlled and it also means the rotor castings are coated right after machining and washing leaving no time for surface corrosion to set in which happens minutes after a rotor is washed and left as naked iron

We call these… GEN 3

Made Using G3000 Cast Iron

EBC Automotive brake rotors are made from G3000 spec cast iron and full specifications and properties can be seen here! Runout figures above this will lead to vibration after 3000 to 4000 miles due to what we call disc thickness variation which is not a warranty condition. So you see this is no cheap import brake disc. These brake discs have the highest integrity and product quality on the aftermarket. An OE quality replacement disc, made of the finest grade iron and a perfect replacement disc for any car.

Every EBC rotor is runout inspected on this machine. Even when manufactured on state of the art precision machines, not even ONE single disc escapes this process guaranteeing perfect disc alignment. If during install you notice runout on your car it will surely be due to a chassis alignment that happens on one in seven cars, usually cased by nudging a kerb or hitting a pothole in the road earlier in driving the vehicle.

Statement Of Quality

EBC manufacture the vast majority of its automotive rotors including

Premium brake rotors in the UK or Europe.

Geometry Issues

One in seven cars suffers geometry problems during its life that can affect steering and cause brake vibration. These are NOT a product quality issue! These can happen by simply nudging a kerb or by driving over a pothole. EBC is not alone in recognising this problem but is the only brake supplier on the planet prepared to offer diagnosis and a solutions.

Installation or hub run-out issues

These cause what is known as DTV. The videos below show how to correct for brake vibration caused by DTV (Disc thickness variation). DTV develops in a car after 3000-4000 miles caused by runout built in to the car or due to incorrect alignment of the rotors at install. This is quite a common fault on modern cars and many cars require this at every rotor change. drivers also confuse hub distortion with a rotor quality issue but in 99% of cases the dtv is a car problem, not a rotor quality problem. you can replace the rotors as many times as you like trying to solve vibration and the problem will only go away for a few thousand miles and then return. this means you have purchased new rotors in good faith but the problem is not solved and will not go away permanently until you perform this procedure. after this skimming of the rotor surface you will have smooth brakes , more effective brakes and zero vibration. it is even a very worthwhile practice when fitting new rotors to have all four rotors skimmed into perfect alignment on your car with this inexpensive procedure.

Rotor Distortion

Rotor distortion due to DTV is very common, in fact one in seven cars has a steering geometry problem either when it is built new or after nudging a kerb or hitting a large pothole. Some drivers still say “My rotors are warped”. Well the engineering facts are rotors do not warp, they are made of cast iron, they are very tough and can be run to red heat and cooled time after time and they will not distort, we do this day in day out on our dynos in the EBC lab. Thats why the whole world still uses cast iron as a vehicle brake rotor material, there has never been anything to beat it and probably never will be. Pro Cut machines Work on both plain rotors and even better on slotted and drilled rotors of all types.

Who are Pro-Cut?

Pro Cut USA is a multi-national and extremely professional Corporation. Their machines are used and approved by many major car manufacturers and used all over the world to do exactly what they do best, correct for rotor mis-alignment no matter how it arises on a car. You cannot achieve this with any other device.

Can't find what you're looking for?

The EBC Brakes team is always happy to help. If you can't find what you're looking for, please don't hesitate to get in touch via our Contact page. But be sure to check our FAQ's first, in case your query has already been answered.