Bicycle Brake Discs

In a few short years since Mountain bikes were developed much has happened to enhance the performance of these great leisure toys including the brakes specifically mountain bike disc brakes. Improved suspension, stronger frames and most importantly lighter units have been progressive developments but surely one feature that has taken this market by storm is improvements to brakes.

Until the end of the 1990’s all cycles were equipped with what are known as caliper brakes or rim brakes which consisted of two rubber or composite blocks brought to bear on the cycle rim by a vee caliper. Not only did this cause shortages in stopping power of the bike brakes but the rim brakes were noisy, they overheated and even melted in faster riding and were almost ineffective in the wet.

Development went on at pace and the disc brake market pioneered by a UK firm Hope technology brought some legitimacy to the mountain bike brakes on offer in the early 2000 years. Initial disc brakes on mountain bikes were only found on riders undergoing downhill riding or racing where the brakes are help on continuously to slow the riders descent. This caused massive overheat of the brakes and quickly consigned rim brakes to the history books for downhill applications. However during the formative years from 2000 to 2005 even cross country or trekking cycles started being fitted from new bike build with mountain bike disc brakes. There were numerous reasons for this other than simply the performance of the brakes themselves, there was a consideration of hype, weight and actual safety of the brakes overall especially when using the bikes in wet riding. Safety being paramount it is now quite uncommon to see any mountain bike being delivered without disc brakes and even the lowest prices units feature this type of brake system.

There are two basic systems on mountain bike brakes employing disc technology being hydraulic units and those activated by cables. Some units even employ a lead screw system to enhance braking power at the cable operated mechanical calipers but nothing brakes as well as the hydraulic disc system.

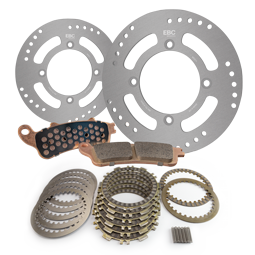

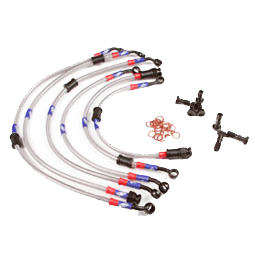

Hydraulic disc brakes are capable of stopping a cycle in half the distance and the disc pads used in these types of brakes last well and work more effectively that rubber rim brakes. The use of disc brakes on mountain bikes has encouraged the development of friction compounds used in the systems and as in many motorcycle and automotive brakes the market is split between organic and sintered brake pad offerings. Sintered brakes on mountain bikes do have one drawback in that the heat generation is significant and in downhill riding with the brakes constantly applied brake overheat can lead to fluid boiling or even to a softening on the hydraulic hoses that deliver the brake fluid to the brakes. Some caliper builders have applied steel hose ends of up to 75 mm in length adjacent the caliper to avoid plastic hose blow up and others have been successful using cable operated brakes retaining the better and longer lasting sintered pads.

It is important if you have a mountain bike fitted with disc brakes to choose your pad compound to match the brake rotor. Many lower cost rotors are un-hardened and are marked with the words “Resin Pad only” meaning an organic pad and sintered pads would damage these brake rotors if used in place of the original pads supplied with the cycle. Generally the brake rotors are hardened and tempered stainless steel units and any type of pads sintered or organic can be used in these brakes.