EBC Brakes are now mostly self bedding – but for track use or extreme street use read below.

The Ultimax, Greenstuff, Yellowstuff, and Redstuff EBC pad grades come with a brake in coating that scrubs the rotor surface, accelerates pad seating times, and provides a strong brake effect for the first 100 miles of use as your pads seat themselves. After the first 100 miles or so, unless you are going to drive aggressively, there is nothing more to do meaning – most drivers happily use and enjoy their brake’s excellent performance for tens of thousands of miles after this point. If that’s your way of driving nothing more needs to be explained. Just enjoy your brakes.

Fast street driving

If you drive aggressively or in a “Spirited” fashion on roads where it is safe to do so, after seating the pads to your rotors and certainly not before 300 miles of use , you should be prepared for the pad to emit an odour or even exhibit some smoke as the pads burn off what we call “surface volatiles”. Many faster drivers experience this in harder braking and criticize the pad whereas in fact, this is only part of the final high-end bedding in process as the pads see rotors temps of 400-500C for the first time (not normal in everyday driving).

Once seated any brake pad made by EBC or anyone else, performs better once the pad goes through heat curing or what we call “Green Fade” which happens during its first severe use.

- EBC Redstuff – is NOT recommended for track use and self seats during the first 100-150 miles of street driving. With new pads and especially when fitted with new rotors however drive cautiously for the first 300-400 miles during which time dust will reduce and the pads will feel better and better but if you are a driver who works the brakes hard on his vehicle read the above two paragraphs .

- EBC Yellowstuff – is a fantastic fast street high efficiency pad but on the track, its bed in time for use at the highest temperatures needs to be understood, please read below

- EBC Bluestuff – is the pad of choice for entry-level race use and can be street bedded, driven to the track raced and driven home. This pad has good street manners and is also ( if it matters to you where you use your car) street legal to the European R90 tests.

- For serious regular or exclusive Track use – look at our RP series pads which are super fast to bed in (heavily scorched in manufacture) or the new SR sintered series which require no bedding at all, just mating to new rotors on a simple 1-2 laps warm-up

EBC Yellowstuff Bed-in Procedure

- Fast Street use Pre Bed Fade 1 – drive 50 to 100 miles on Public road/highway normal driving to allow the pads to mate up to the disc and establish full contact followed by 8 stops from 80 mph to 30 mph at 300-yard intervals and then coasting allowing the brakes to cool.

Yellowstuff, although track-capable, is no longer recommended for track use on most cars due to its long bed in the process. BlueStuff is now our recommended entry-level race pad for all vehicles, which as a track hybrid is still great on the street and even better on track. But if you are to use Yellowstuff on the track, follow the below Fade procedures;

- FADE 2 – After the basic street pre-bed above is performed on the road or at the track if installed there …..Perform 10 medium pressure snubs at the track from 80-20mph leaving 300 meters between each snub (approx 0.4g decel)

Allow pads to cool for 15 minutes minimum after coasting to the pits allowing brakes to cool a little. - FADE 3 – Perform 6 high-pressure snubs from 90-20mph with a maximum acceleration between consecutive snubs. (approx 0.8g decel, or 80% of an emergency stop)

Allow the brakes to fully cool for a minimum of 1 hour before the race session.

We advise using disc heat paint to ensure green fade is avoided, continue reading below for more details

Real-world experienced driver – faster street bedding routine.

- We call this real world as it explains in a realistic and safe way how to accelerate this bed in the process. First, make sure you achieve the pad seating – we’re now going to bed the pads in with what we can describe as using “engine torque”.

- On a safe straight road with no cars close behind or in front at approx. 40-50 mph apply the brake to 30% or so pressure whilst continuing to press the accelerator to main vehicle speed for as long as safe to do so, you will need approximately a clear quarter mile to do this so make sure you have that. This will drag the brakes, get them hot and take them past the 400-500C level required for bed in and you may even smell brake odour. You may feel the pedal go a little spongy, if it gets too soft abort the process and start again later. What is too soft? Too soft means that you feel that the brakes are not responding well.

- Release the brake and coast for a mile, slowly, unless you have to make a stop.

- If you have to abort the process part way through, repeat it as soon as safe to do so.

- Coasting after the bed in to allow discs to cool as you should not park the vehicle with HOT brakes. So be sure you have a road where it is safe enough to do this procedure with no imminent bends or stops in front of you so you can roll for a while and allow discs to cool, but if you need the brakes USE THEM

- Allow the brake to fully cool ( if possible overnight) and repeat the exact same process again.

- Your pads should feel entirely different to before the process, they should feel sharp and much more responsive. This process is called eliminating “Green fade” by burning off those surface volatiles.

- You will see blue marks on the discs after you stop, these will go away in a few miles.

EBC Bluestuff Bed-in Procedure

- Perform the Street Pre Bed Fade 1 routine as above (either on the road or at the track if installed there ) followed by Fade 2 at the race track.

- The latest Bluestuff DM3362 and Low Mu versions should only take Fade 2 and a 15 minute cooling time to be ready to race.

- Fade 3 should not be necessary unless poor disc condition has prevented proper seating but if you have time DO perform Fade 3.

You CAN use the “Real-world experienced driver – faster street bedding routine”- described above if you are bedding the pads in on the street

Find this complicated? – we tend to agree but all organic pads no matter which brand do need some bedding in to avoid loss of brake and a lot depends on rotor condition, the slightest hollow of the rotor surface will extend the bed in times a lot. So being accurate is important.

How to check if pads have heat cured or chemically bedded – Brake bedding in causes heat and it is strongly advised to monitor this heat using heat paints TWICE during bedding in on Blue and once only with RP series pads. What you do is, apply the heat paints on the outer edge of the rotor, run the pads for enough stops (8-10 stops ) to pass the 430C temperature ( 800 F ) which will be Fade 1, allow a few minutes for the system to cool and take a look at the heat paints to ensure they have passed the 430 C indicator, reapply new heat paints to a different cleaned area of the disc and drive again for 6-8 more hard stops which will take you past Fade 2 where temps should pass 430C (800F) again. Full cool down needed here of at least 20-30 minutes and if you CAN… overnight cool. You need to see the 430C heat paint go off TWICE to have completed Fade 2.

Fitting new discs at pad change also adds to bed in time as even if the discs are flat and smooth the pad and rotor have to “Square up” to each other and achieve 90% surface contact. As you use your pads on either a new or old disc stop every couple of laps and look for the blue-grey contact patch gradually widening across your rotor surface and don’t race until its almost a full sweep contact, any doubts pop the pads out and look at the surfaces to evaluate contact patch sweep.

Why so long to bed in any way – We can (but don’t) sell pads that are classed as soft and bed in even faster or very abrasive pads that scrub away at the rotor, cause lots of dust and give the impression of a shorter bed in time. So the balance here is to make a variety of pads according to the different driving styles and events so that users can choose what’s best for them.

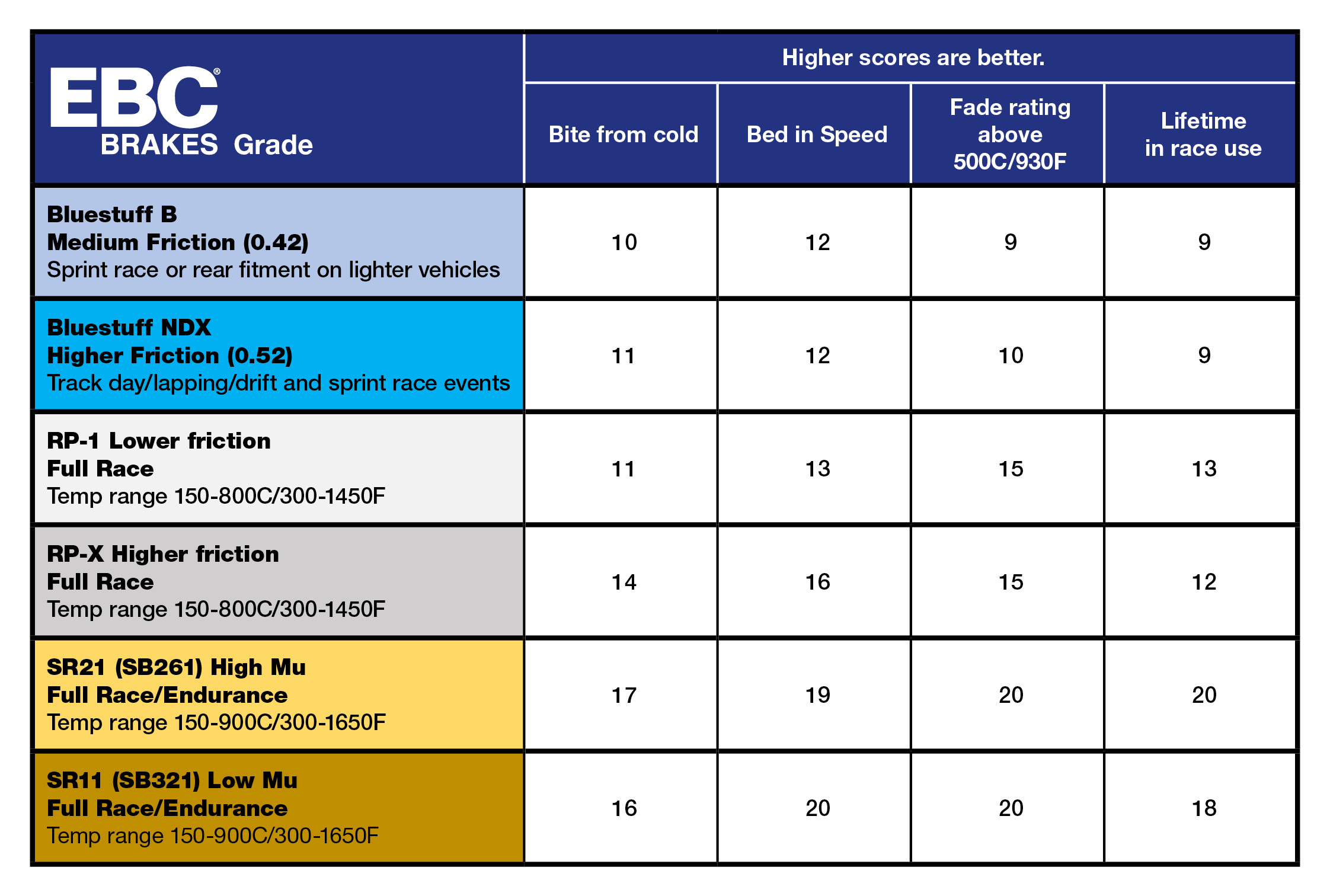

Pads wearing too fast – Trackday or what the USA market call “Lapping” events just doing a few laps to enjoy your car are a tough test on brakes, Extra vehicle weight, seats, and spare wheel, etc and standard calipers make this kind of driving a tough test on brakes and you may need to consider moving up a grade. See this chart as a guide on types of EBC compounds for different driving events

Pads still fading after bed in – it’s not JUST getting the pads flat and parallel it’s about taking them past their green fade point AFTER achieving a good contact band. for this reason, disc heat paints are very useful. Pads should be driven with caution until bedded flat and you have passed this green fade point at least twice and then allowed pads to cool so the disc is below 100C. Green fade only happens on organic pads – much less with our RP pads and not at all with our SR pad range. There are two ways to know if you have passed the green fade point – one is the clever way with heat paints – the second way is to guess… So heat paints are the better option

Green fade points are 400 C or 650 F (Fade 1) and then the same again ( Fade 2) for the two fades required with Bluestuff and 400C/800F just the once for RP series pads RP pads. For this reason, EBC Heat paints first level indicate at a temperature of just over 400C/800 F so that once this paint changes colour, one fade cycle is done.

EBC RP-X™ and RP-1™ Race Compounds Bed-in Procedure

- No Street Pre Bed needed or legally allowed, these are pure race track compounds – BUT only in the EU markets is anyone going to worry about this. Generally, the EBC RP pads are quite safe to use on the streets and many drivers fit them and drive to and from race tracks happily with very limited noise. RP pads don’t need to “Warm-up” and are as good as or better than most stock pads in lower-speed highway driving. Full potential comes though when you really work these pads though and that is why we class them as a race pad.

- Single gentle lap to seat pads to rotors followed by Fade 3 as above should be all that is needed

EBC Sintered SR11™ and SR21™ Bed-in Procedure – in stock now for most of the range

- These are a new generation of Sintered pads and do not require any chemical bedding. Pads merely need mating to the disc/rotor which again depends on rotor/disc condition but if flat or new this should take 3-5 snubs as mentioned in Fade 3 above – at the track.

- No Street Pre Bed needed or legally allowed, these are pure race track compounds, again we have many drivers who use these on the open road with no complaints but remember in the EU legislation makes it actually illegal to use a nonapproved pad on public roads.

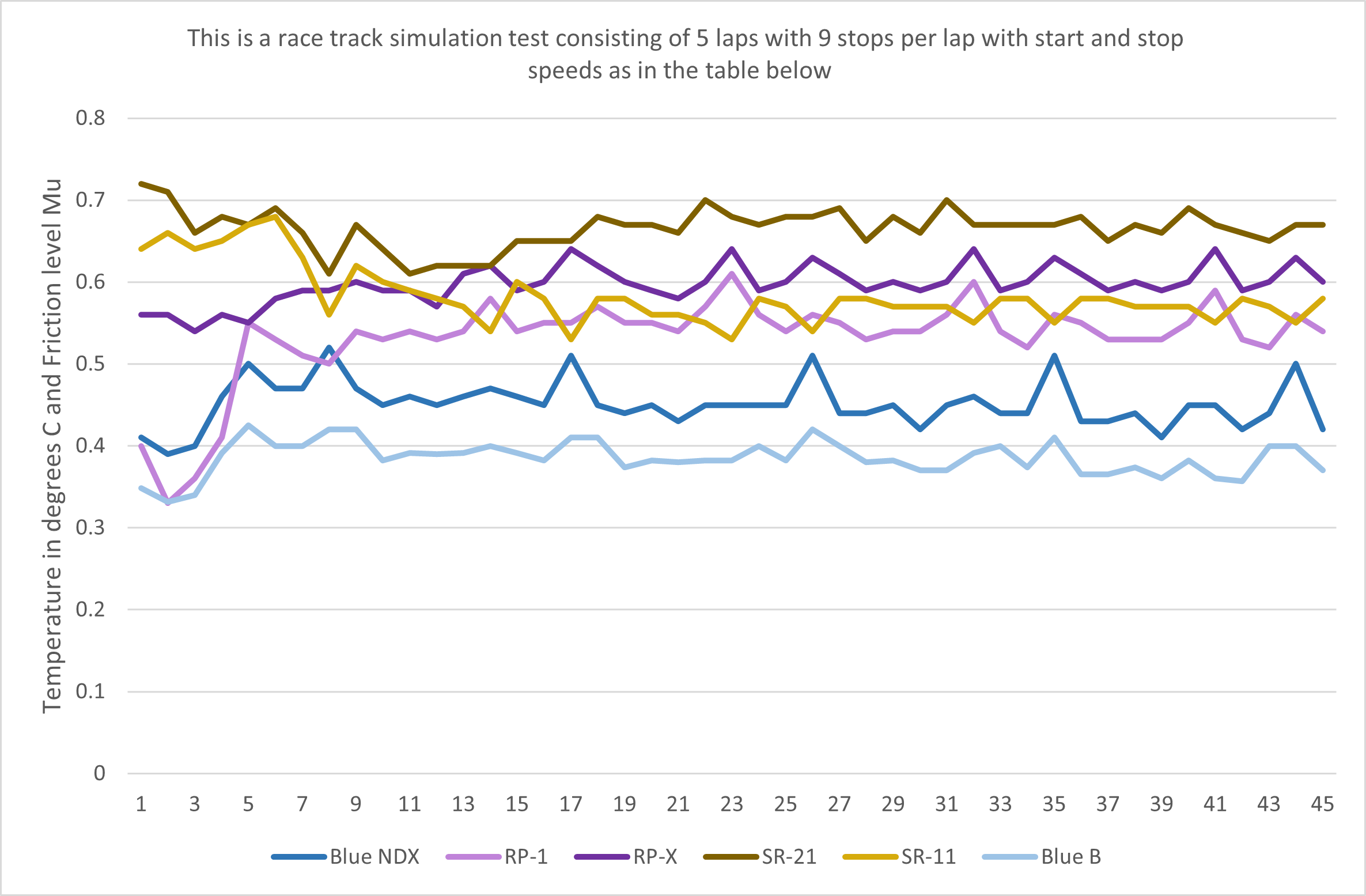

Comparison of friction levels of the main EBC race materials below

The graph should not be confused with a “ fade test “

Any falloff in friction depends on the deceleration amount from V1 to V2 – and heavier stops see more fall off.

Still, in every case, the brake effect is still very significant and reliable

The test is a made-up lap of 9 stops repeated 5 times to give 45 stops in total.

All stops are at 0.7G but have different brake-on and brake-off speeds as shown below (in km/h) – the slower stops tend to produce higher friction levels irrespective of the material which is what gives the variability.

| Stop | V initial Km/hr | V final Km/hr |

| 1 | 224 | 144 |

| 2 | 200 | 80 |

| 3 | 208 | 128 |

| 4 | 192 | 64 |

| 5 | 144 | 48 |

| 6 | 208 | 128 |

| 7 | 216 | 112 |

| 8 | 144 | 40 |

| 9 | 192 | 96 |

Check Your Brake Fluid and Caliper Condition

Surprisingly many drivers don’t pay enough attention to fluid. A high temp fluid such as EBC BF-307 which is an extremely pure glycol fluid and has a dry (new) boiling point of 307C ( 580F ) should be used, change fluids regularly in track use to maintain firm brake pedal, avoid vapor lock and deliver a linear brake response. Fluids should be changed every two years for normal street use and every 2-3 track events for track-day and every event for full hard race use.

EBC strongly recommends the use of Disc heat paints to monitor disc temperature and caliper heat strips in racing to check caliper is not overheating. If calipers are dragging temperatures can rise above the seal upper limits and damage seals. Sliding single piston calipers should always be serviced ready for track driving as often sticking or seized calipers cause blame to be placed on the pad compound in error.

Can't find what you're looking for?

The EBC Brakes team is always happy to help. If you can't find what you're looking for, please don't hesitate to get in touch via our Contact page. But be sure to check our FAQ's first, in case your query has already been answered.